JAYSHREE TABLET SCIENCE

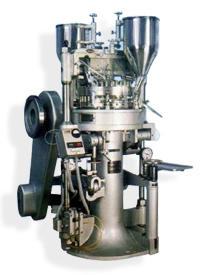

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to JAYSHREE TABLET SCIENCE

Sealed Groved Punch

Granule contamination during the tabletting process can cause costly manufacturing problems. 'Black Spots' on tablets resulting in high numbers of rejected tablets, increased wear of punch guides and tightening of upper punches can result in excessive machine down time and high maintenance costs.

Eurostandard Punch Bellows are designed to prevent guideway and tablet contamination during the tablet compression process, a vast improvement over traditional dust caps used in the pharmaceutical, confectionery and allied industries.

The risk of oil contamination from the machines lubrication system is reduced when Bellows are fitted onto upper punches forming a flexible seal. This product has been developed for Euro 'B' and 'D' type punches, which have the Holland Universal seal grooves. Once the punches are positioned in the turret, a simple operation of pushing the bellows over the punch tip and onto the barrel, results in the Bellows forming an excellent seal to protect against product contamination.

The Bellows are manufactured in High Tear Strength silicone, coloured Blue, in compliance with F.D.A. approved regulations and conforming to ISO 9000 quality standards.

Use of the bellows will improve the punch performance within the press by reducing the amount of contamination in the punch guide, and help improve the life of the tooling.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.